High Heat Dissipation Substrate

■ Background

In EVs, 5G communication systems, and data center servers, heat generation is a serious issue that directly affects the performance and life of equipment. Therefore, it is important to suppress heat generation itself.

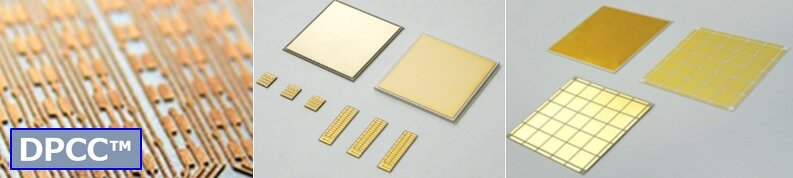

AOI Electronics offers high heat dissipation substrates that combine substrate materials with excellent heat dissipation and highly reliable wiring materials.

【Applications of this technology】

Automotive power supply boards , Industrial semiconductor control boards , Large display control boards , Server power supply boards

■ Feature

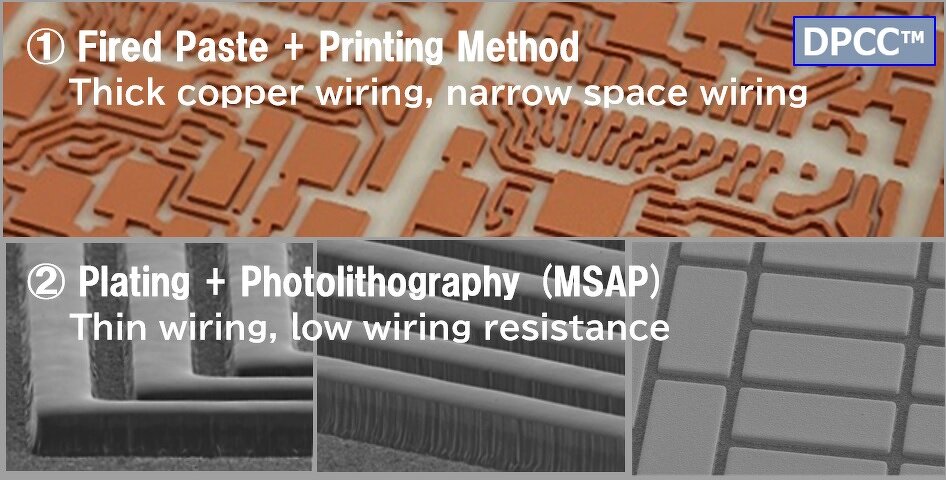

High-definition wiring formation by two methods

・Wiring thickness can be widely from 10 to 1,000 μm(*) (* In the case of DPCC, it depends on printing conditions)

・Various substrate materials are available (alumina, aluminum nitride with higher thermal conductivity, silicon nitride, etc.)

・High quality assurance by One-Stop manufacturing, available both as substrate and after device mounting.

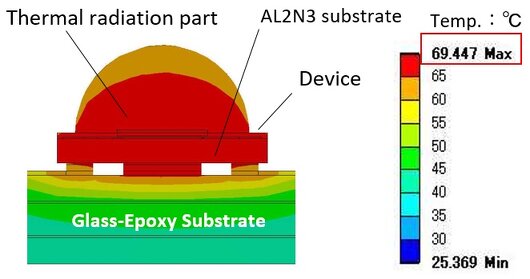

・Proposal by Thermal Simulation

Left: Device analysis example of aluminum nitride substrate

(Size 3mm□ Applied power 1W)

■ Structure

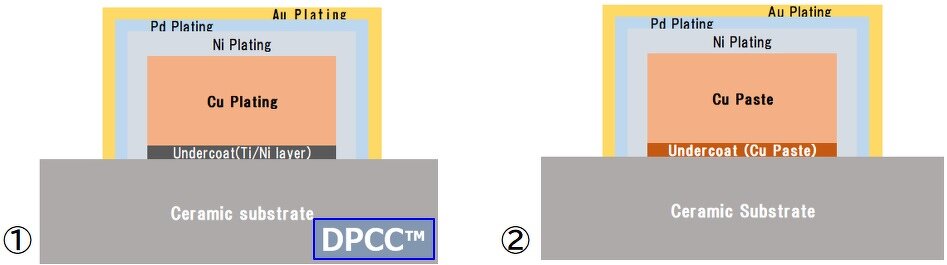

① Thick wiring structure by sintered paste + screen printing

② Highly reliable structure by plating + thin-film photolithography

■ Application

Automotive Power Supply Substrate, ECU Substrate

Industrial Equipment control boards for semiconductor devices, refrigeration elements

Lighting LED Lighting Substrates, Large Display Control Substrates