DPCC™ : Direct Printed Copper on Ceramics base substrate

■Feature

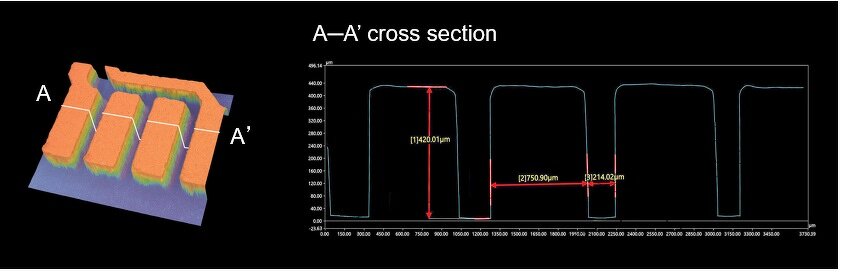

① Thickness Over 1,000μm* (* Depends On Printing Condition)

・Thickness suitable for power semiconductor substrates

・Can form areas of different thickness on the same wiring

② Pattern spacing Min.25μm* (* Depends On Printing Condition)

・Wiring by screen printing using copper paste

・High-density wiring beyond conventional DBC/AMB etch rules

③ Various Ceramics Substrate

・Available Cu wiring patterns on various ceramic substrates

・AL2O3 , ALN , Si3N4

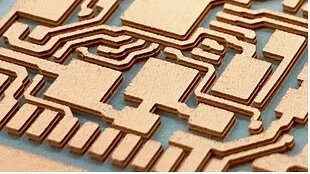

■Shape of wiring

・Good rectangular shape and flatness on surface

・Form L/S that is difficult to achieve with etching method