Recently, there has been an increasing demand for flip-chip packages that use Cu-pillar bumps for power supply ICs

in order to support miniaturization and high-speed switching frequencies.

Advantage is the turnkey process. We propose excellent flip-chip packages by fusing Cu-pillar forming technology

with package assembly technology on wafers.

Feature

- Turnkey services (6" & 8" wafer)

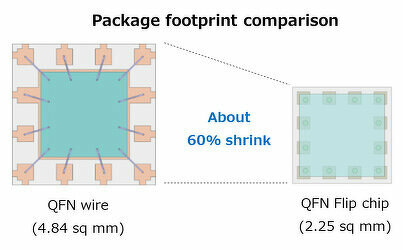

- Downsizing (60% size reduction compared with wire type)

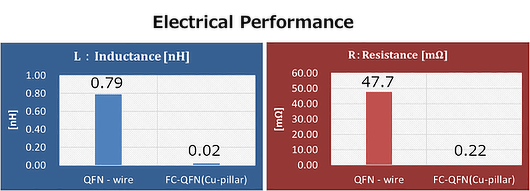

- Reduction of signal inductance (For high speed switching frequencies)

- Large current (low resistance)

- Wettable flank structure option for automotive

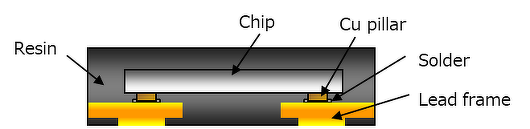

Structure

Application

・ DCDC converter

・ LDO / Low Dropout Regulator

・ PMIC / Power Management

・ High speed switching device

・ RF switch, Antenna tuning switch